From the Big Picture to the Tiniest Detail – OCS Quality Control for Your Products

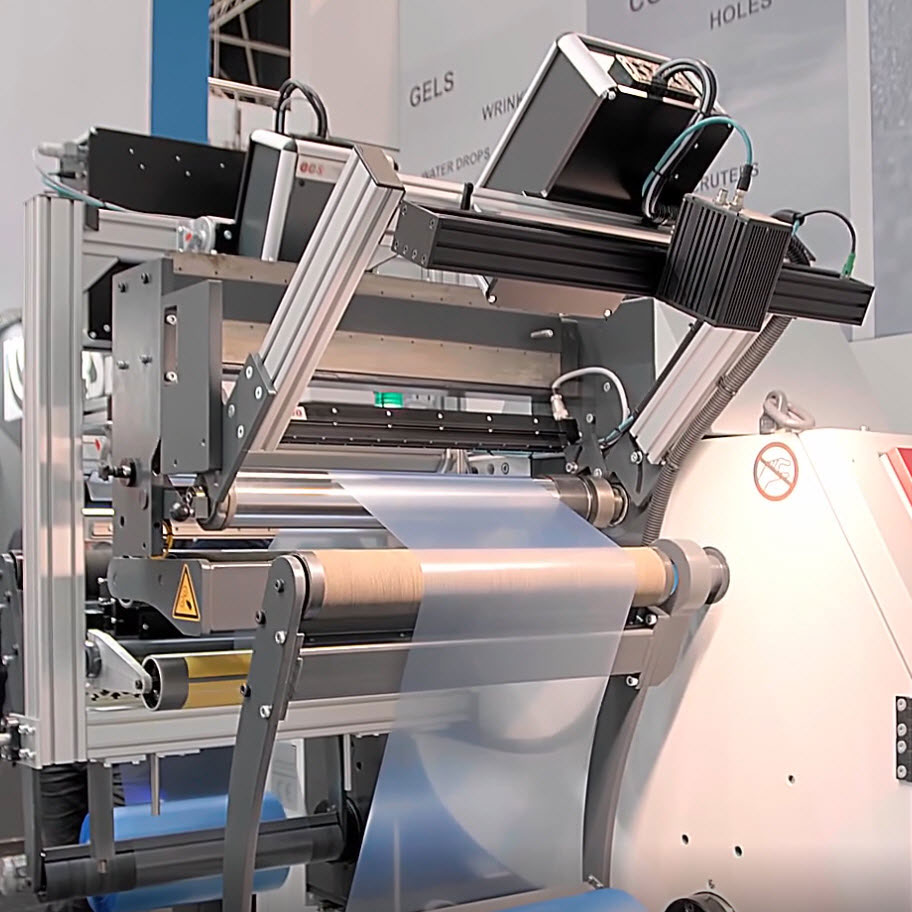

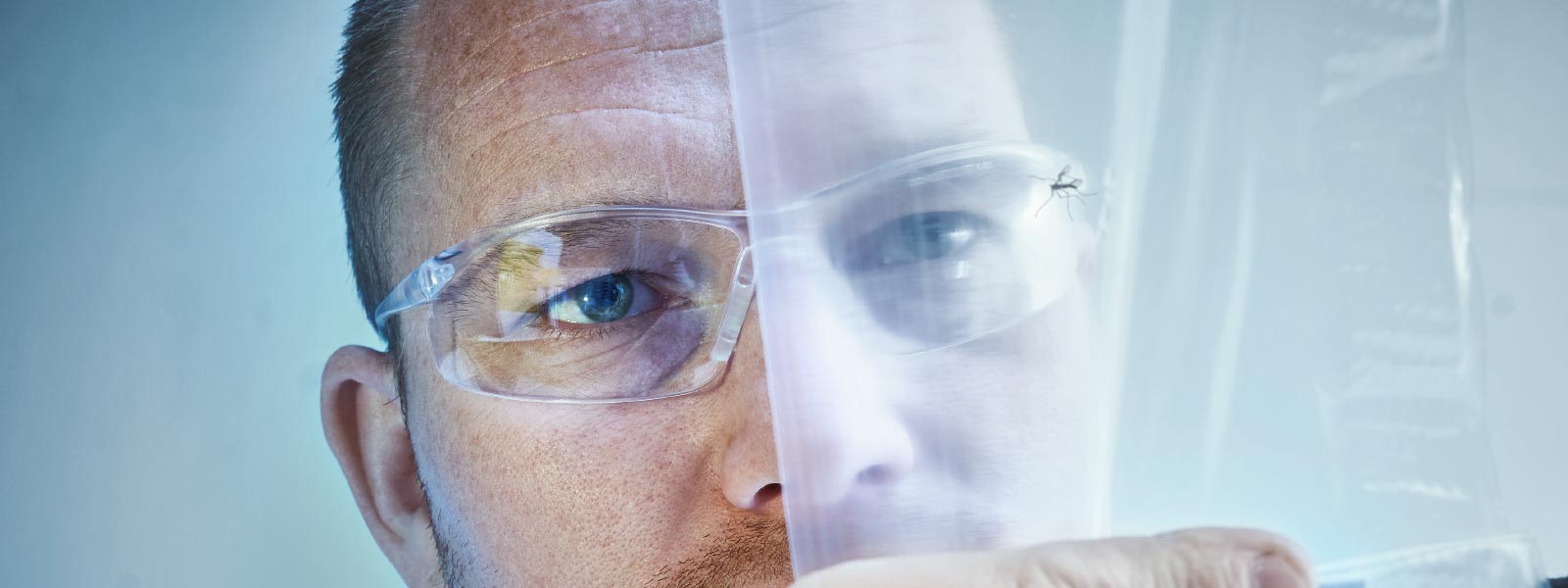

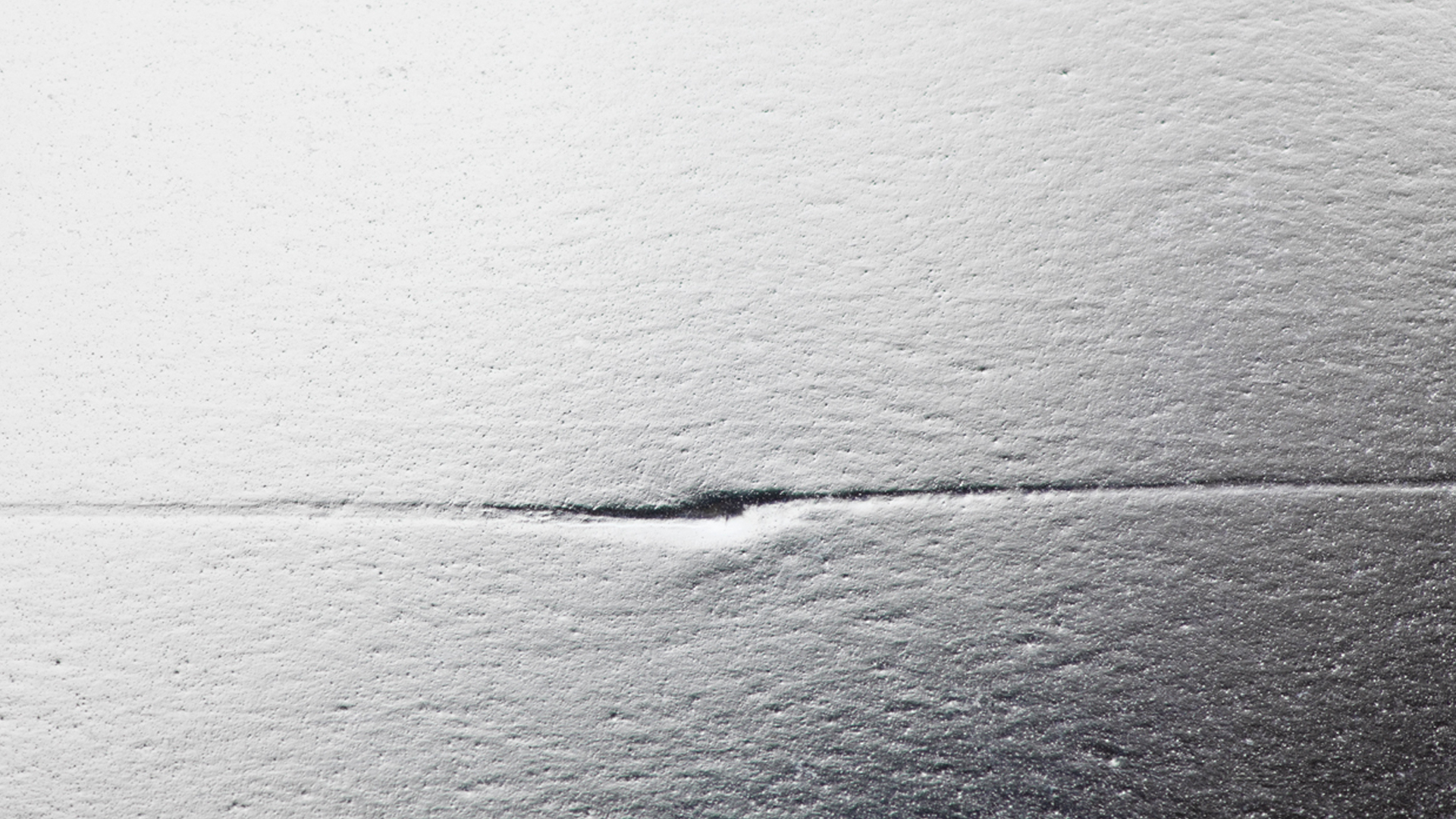

Manufacturers and converters of film must consistently guarantee flawless product quality. This is what led us to develop the OCS Wide-Web Inspection System. The system is able to check the entire width of the material surface during the production process and guarantee 100% quality control for films, coatings, laminates and non-wovens.

The result: a considerable reduction in defective goods and therefore significant time and cost savings.

A large number of well-known film manufacturers and companies in the plastics processing/converting industry put their trust in OCS Wide-Web Inspection Devices to ensure excellent quality control of their products. Windmöller & Hölscher KG use the FSP600 Web Inspection System in blown and flat (cast) film production and work with a width of approximately 2,800 mm in a pilot plant.

The OCS headquarters in Witten have a training centre that offers courses for the professional use of the FSP600 System. Here you can learn more about operating and configuring the system under real production conditions. Our experts will assist you with their in-depth specialist knowledge during the training process.

Application Areas

- Blown film, cast (flat) film & plate lines

(PP, PET, PE, ABS, PC, PMMA etc.) - Coating systems

- Calender lines

- Biaxial stretch film lines

- Extrusion coating systems (aluminium) and painting lines

- Surface protection films

- Medical and pharmaceutical films

- Optical films

- Food and barrier films

- Hygiene and nappy films, non-woven and laminates

- Technical films

- etc.

Clever use of defects

“OCS Inspection Systems provide the basis for our process control. By means of the extended networking of complete data stocks from the OCS analysis software and our PDA system, we can react faster to quality variations and assist in the reduction of scrap, rework and machine downtimes.” Mondi Case.

Quality assurance from the start

“Thanks to the OCS camera systems, we have been able to increase output in recent years and significantly reduce customer complaints, which not only has an economic advantage but also an ecological advantage due to the low waste.” Klöckner Pentaplast Case.

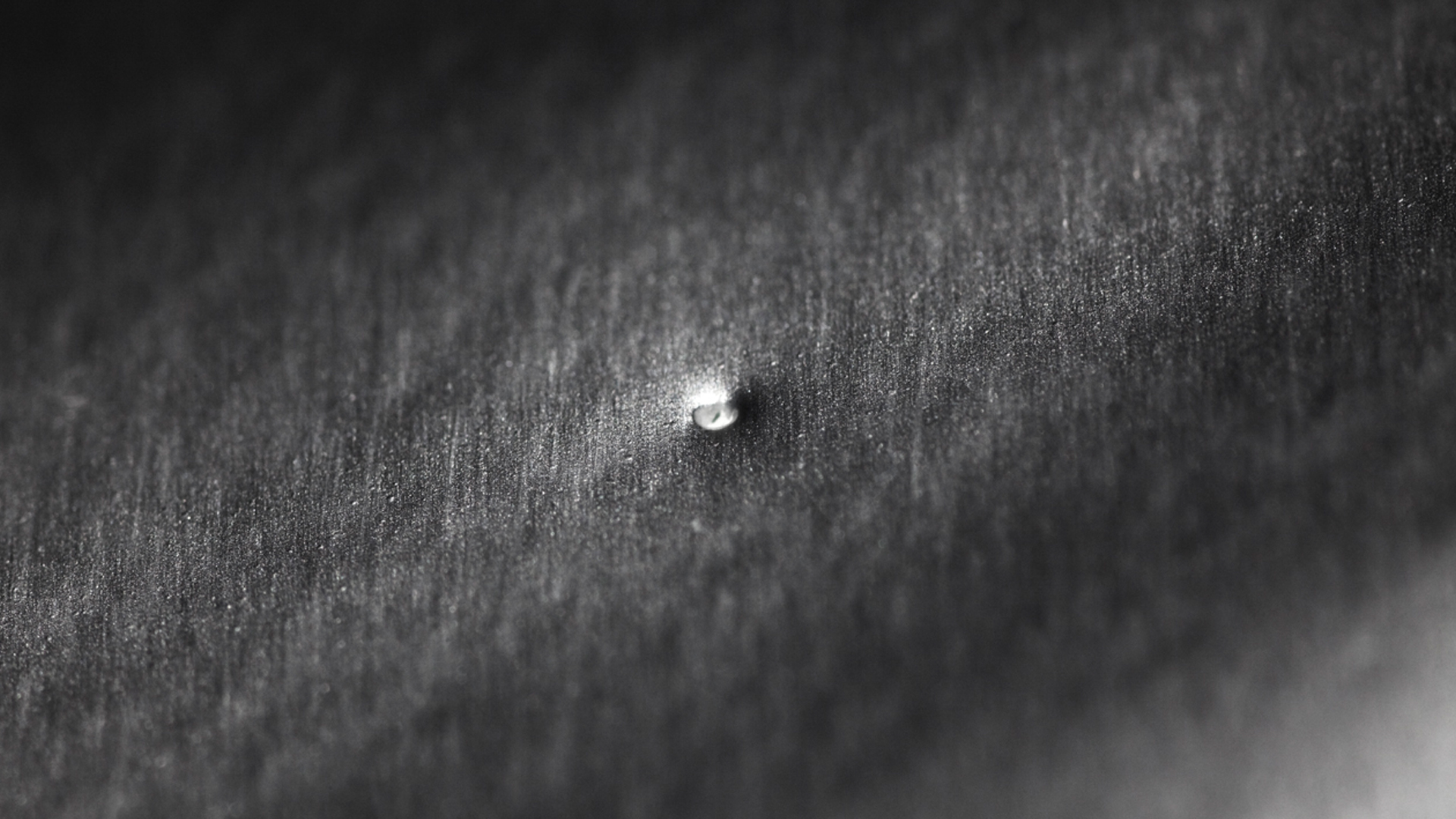

Purity Control OnRoll (PCR)

With the development of Purity Control OnRoll (PCR), the film manufacturer is able to inspect the film on the roll in the winder and identify all types of contamination. PCR can be easily integrated into the winding unit. In addition, it can be integrated into the existing FSP600 System software or used as a stand-alone solution. PCR allows inspection widths of up to ten metres and is particularly suitable for cast (flat) and blown film, biaxial stretch film, laminating and slitting lines.