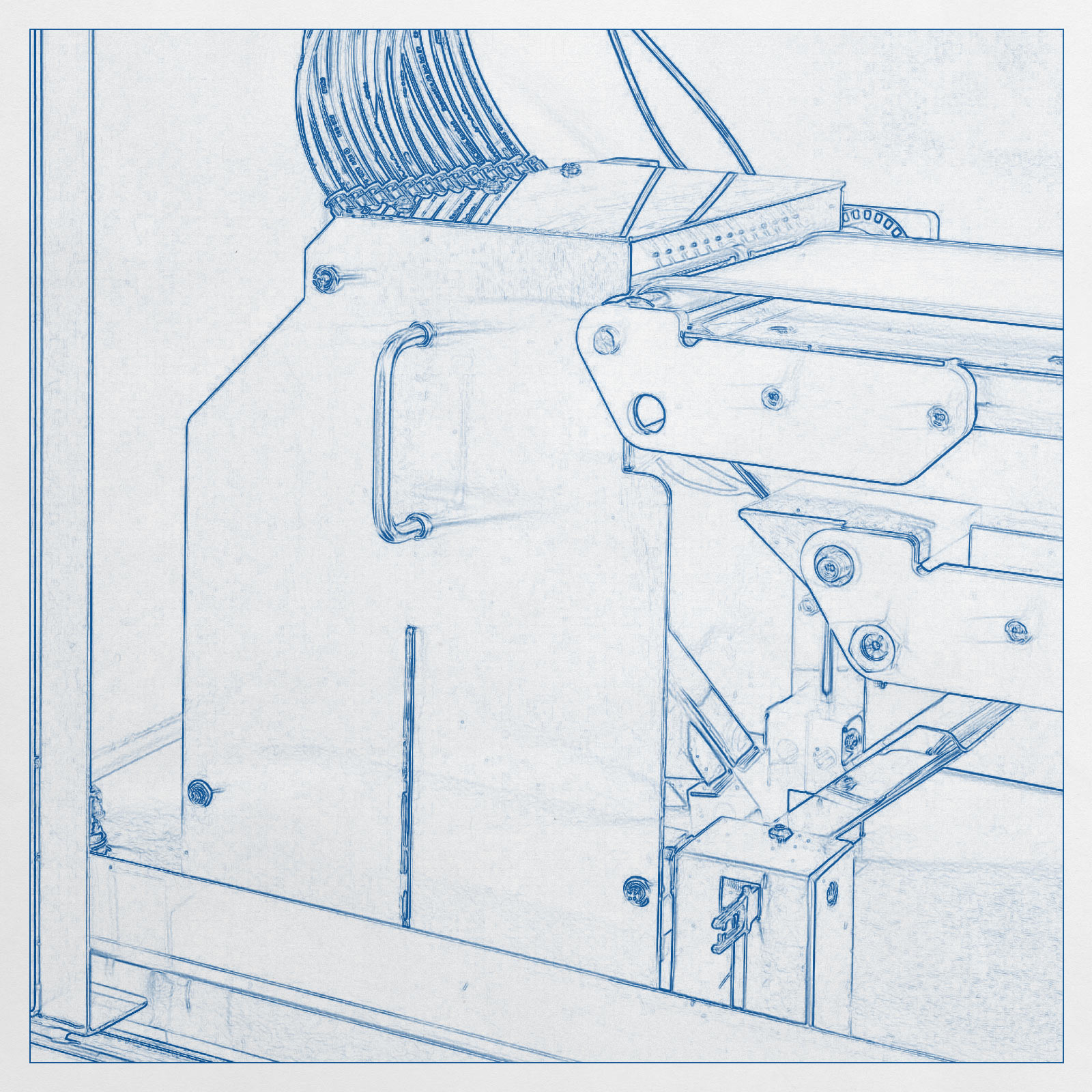

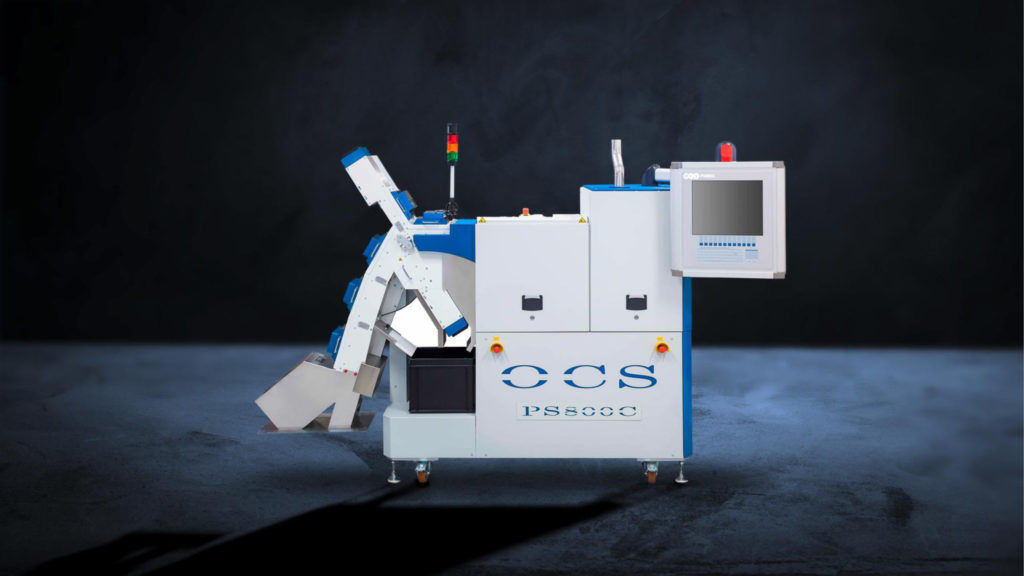

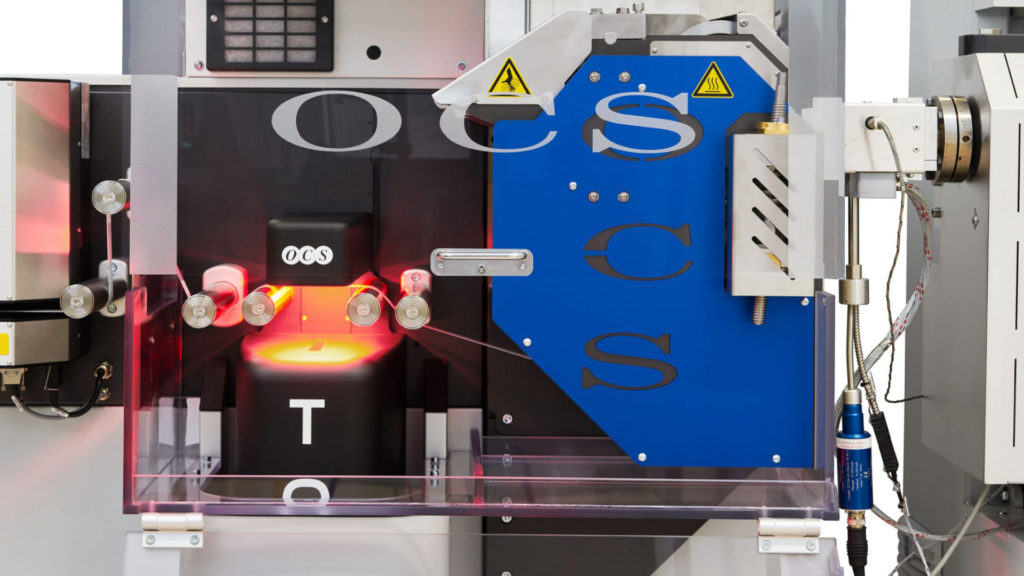

X-Ray Pellet Scanner (XP7)

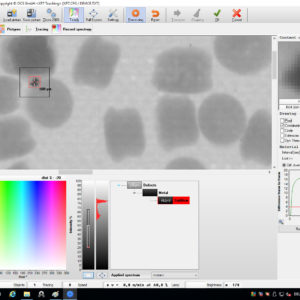

The new OCS XP7 X-Ray Pellet Scanner detects metal defects in highly transparent and opaque pellets, which improves the polymer and product quality. The innovative X-ray technology in the measuring system of the XP7 analyses images of the pellet stream in real time. Due to the different absorption of the X-rays in the metal and in the polymer, the embedded metal particles can be detected from a size of 50 µm. Contaminated pellets are sorted out by a multi-track air nozzle system.

Testable Raw Materials

- Highly transparent pellets

- Opaque pellets

Features

- High-resolution X-ray image

- Smallest detectable contamination size: 50 µm

- High-speed throughput rate of up to 600 kg/h depending on pellet properties

- Specially developed for the detection of metal defects in pellets

- High-quality and proven radiation protection

- Visualisation of the real-time results

- Multi-track air nozzle system for sorting out contaminated pellets

Sales Team

T +49 2302 95622-0

F +49 2302 95622-33

info@ocsgmbh.com

www.ocsgmbh.com

Address

OCS Optical Control Systems GmbH

Wullener Feld 24

58454 Witten

Germany