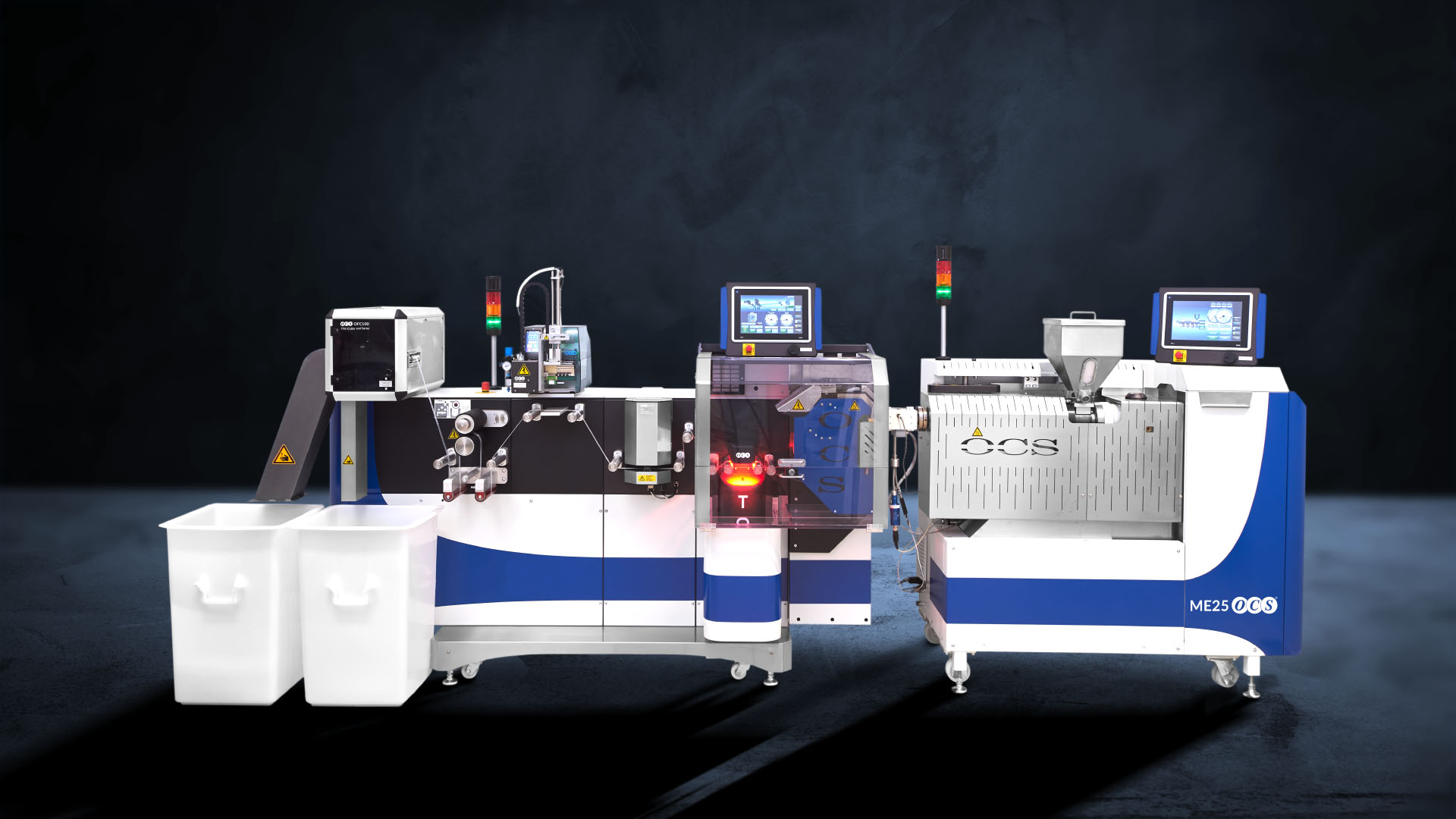

Tape Line (TCA®)

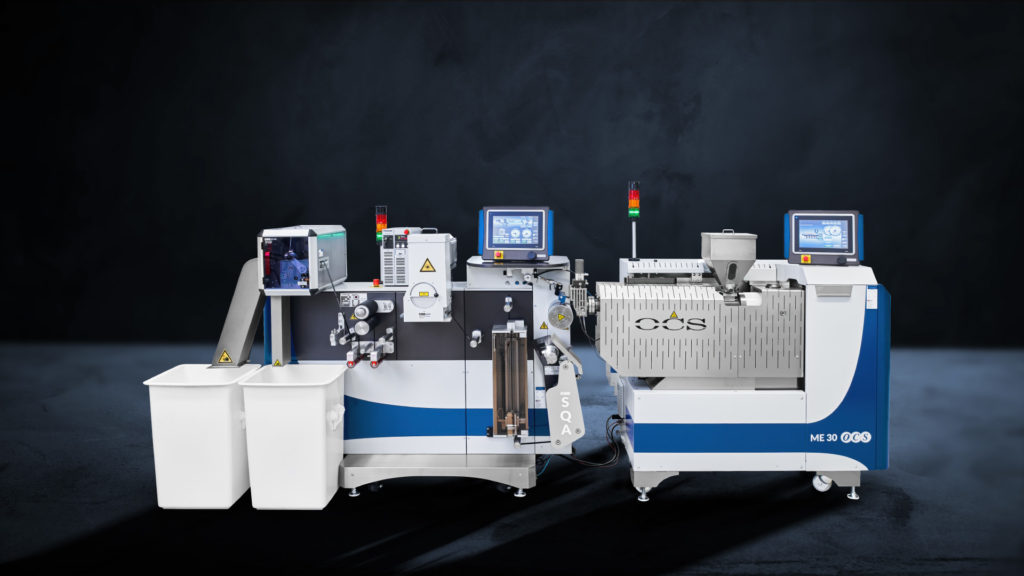

The OCS Tape Line Type TCA® is used for testing transparent polymer films (tape). It consists of the OCS Measuring Extruder (ME) and the OCS Modular Film Analyser with Calender (MFA-Calender). Our calendaring system has been specially developed for the wire and cable industry. It presses and cools the extruded polymer film (tape) from both sides, thus ensuring a smooth and consistent surface thickness for optical anlysis.

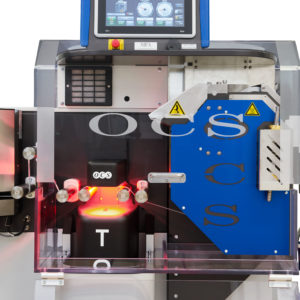

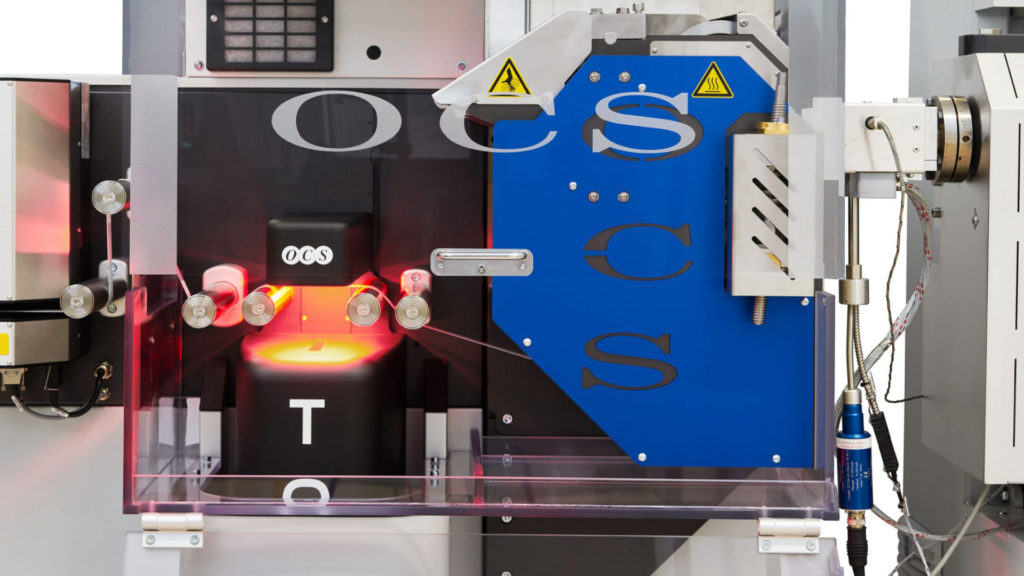

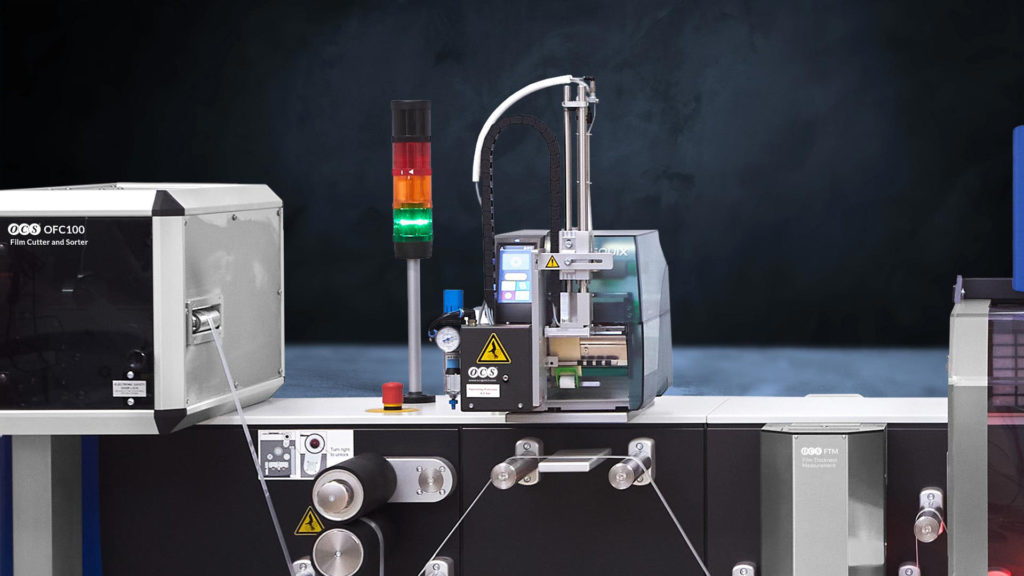

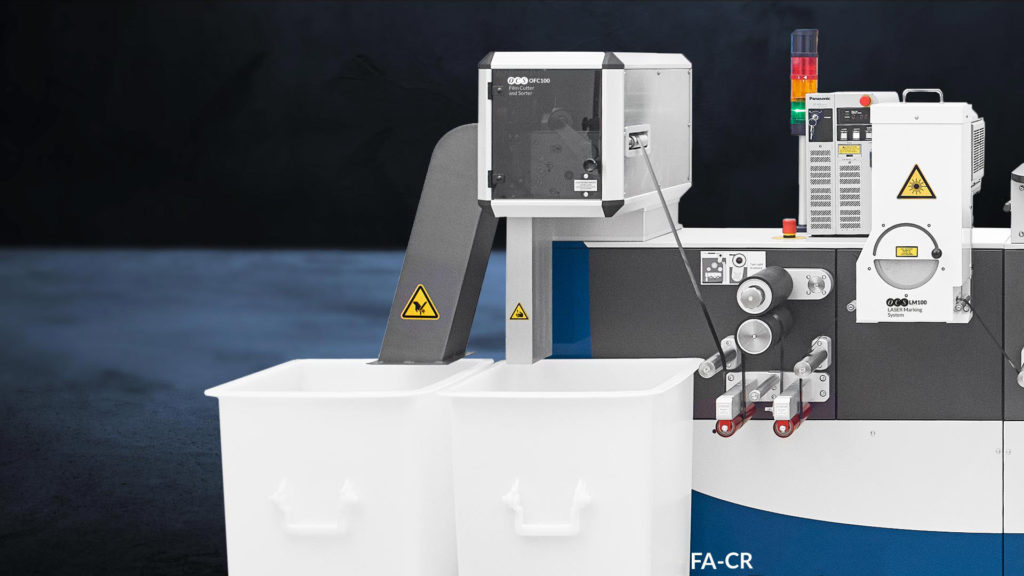

The Tape Quality Analyser (TQA100) contains a high-resolution camera system that detects contaminants, gels, black specks, fibres and metal particles. The detected errors are marked by the LASER Marking System (LM100) or the Label Printer (LP100). The polymer film is then cut into strips using the OCS Film Cutter and Sorter (OFC100) and sorted into appropriate containers. Additional physical, chemical and optical test systems can be integrated on customer request.

Testable Raw Materials

- Pellets/transparent polymer films (tape), powder and flakes

Module I + II (included)

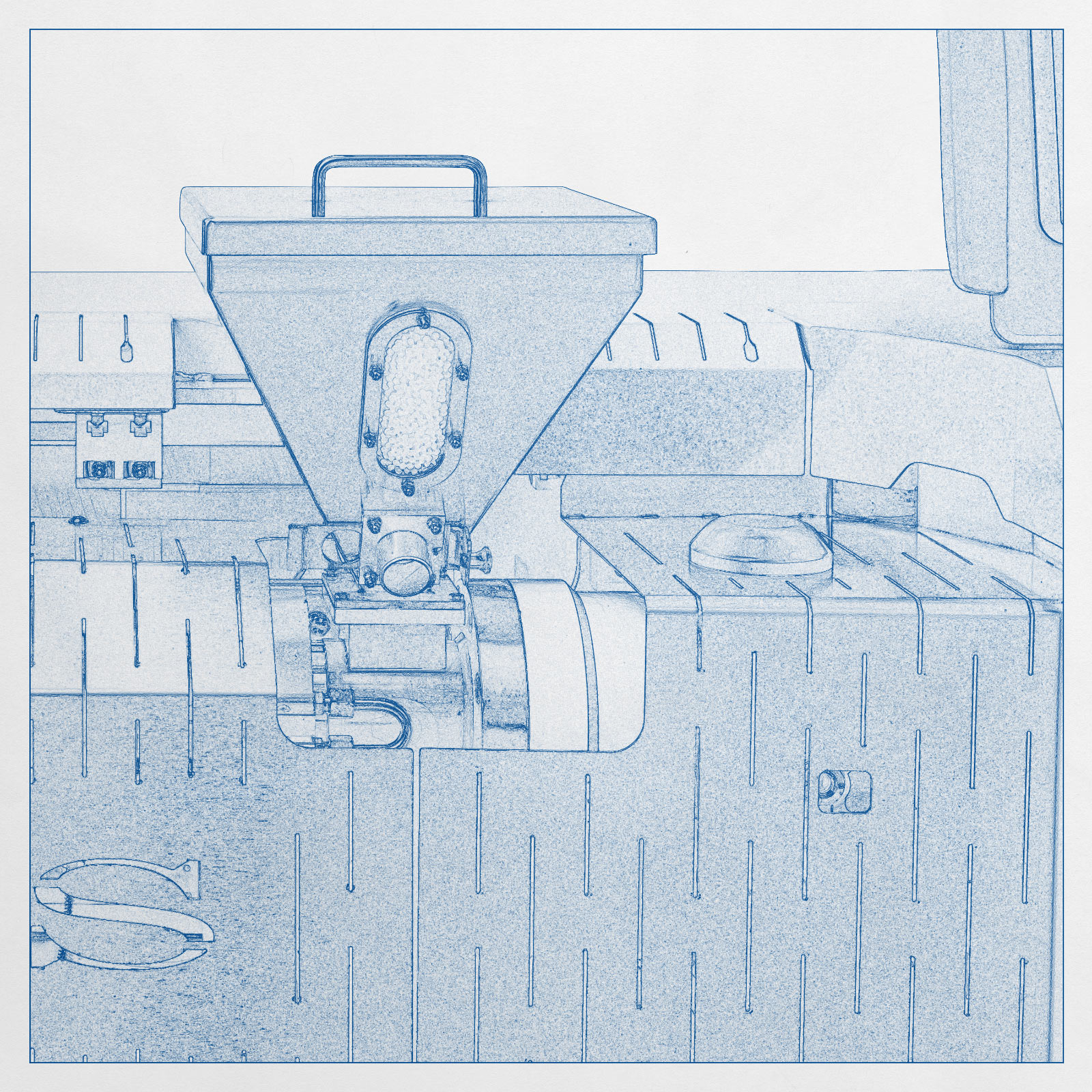

- Measuring Extruder (ME20/ME25/ME30) with fix lip die of 50–75 mm

- Modular Film Analyser with Calender (MFA-Calender)

- Tape Quality Analyser (TQA100)

Features

- Measuring Extruder (ME) comes with flexible height adjustment (infusion position)

- Maintenance and cleaning positions of the Measuring Extruder (ME) can be approached via electric motor

- Modular architecture of the Modular Film Analyser (MFA) to facilitate customisation of additional measuring devices

- Operation via touch panel with data trend as well as optical and acoustic alarm functions

- All system parameters are monitored and saved in the touch panel control system

- Several options for data communication available

Sales Team

T +49 2302 95622-0

F +49 2302 95622-33

info@ocsgmbh.com

www.ocsgmbh.com

Address

OCS Optical Control Systems GmbH

Wullener Feld 24

58454 Witten

Germany