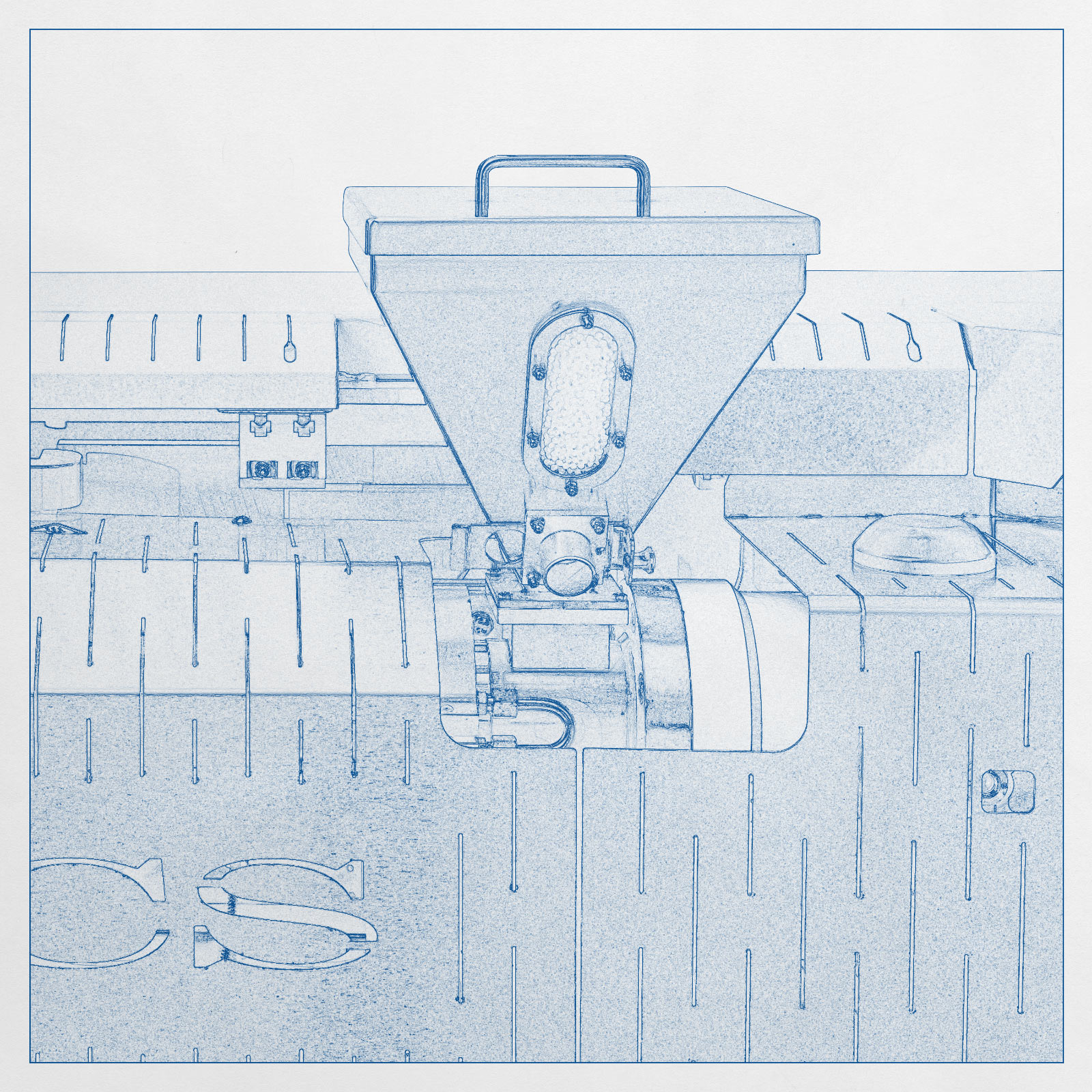

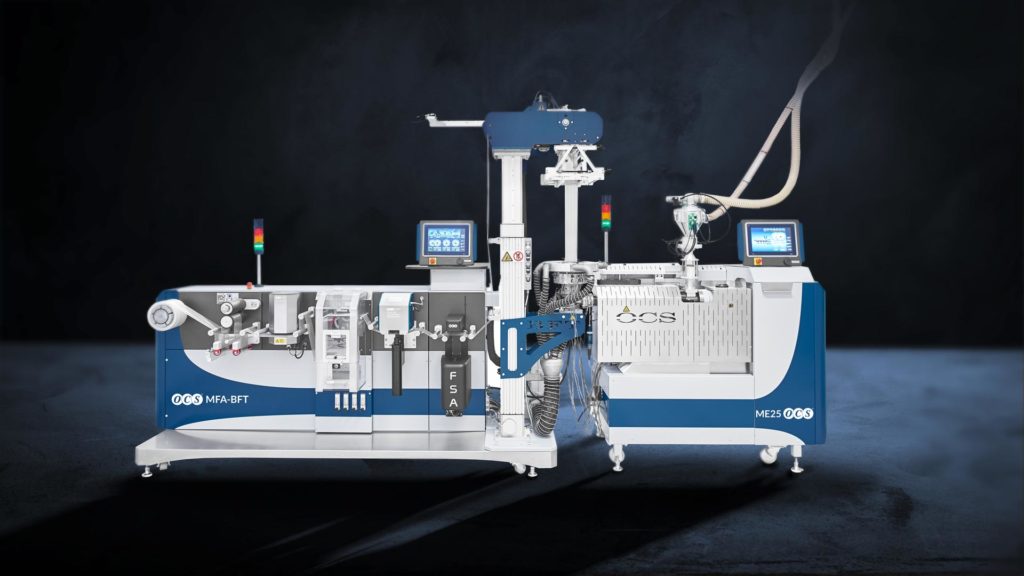

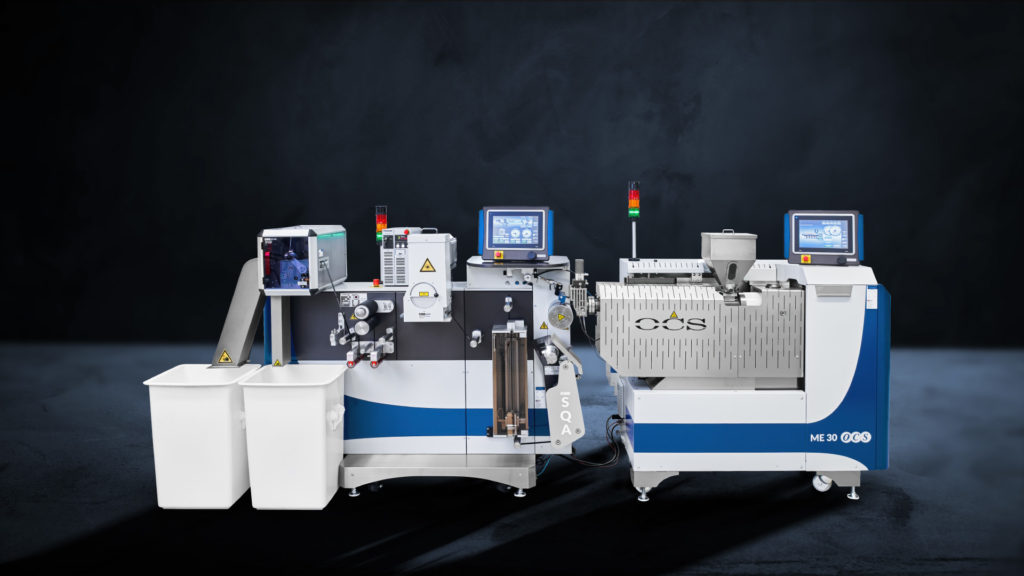

Measuring Extruder (ME20/ME25/ME30/ME40/ME45)

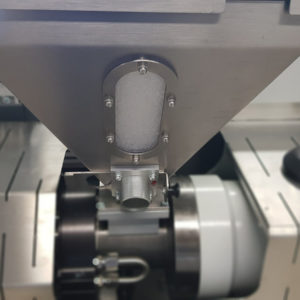

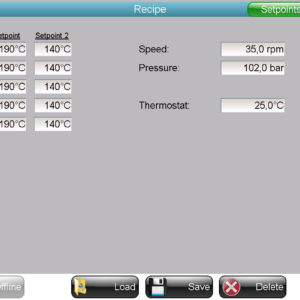

The OCS Measuring Extruder (ME) is used for the production of polymer films for laboratory and small series production. The extruder is equipped with a flat film die and, if necessary, a downstream OCS Modular Film Analyser to enable further quality measurements. The system is controlled via a touch panel to set up device parameters and recipes. In addition, the optional Remote Control Function allows the Measuring Extruder (ME) to be displayed and controlled from various locations. Another feature is the automatic turning system, which allows easy cleaning of the extruder barrel, die and screw. The extruder then automatically returns to its exact setting position to simulate the same condition as during production.

Features

- High-quality laboratory design with plasticising unit in stainless steel

- Robust, precise drive technology

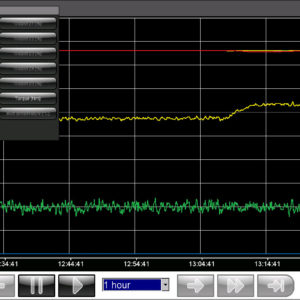

- Operation via touch panel with data trending as well as optical and acoustic alarm functions

- Temperature zone control through self-optimising PID controllers

- Simple data and recipe processing

Compatible with

- OCS Cast Film Line

- OCS Blown Film Line

- OCS Tape Line

- OCS Modular Film Analyser (MFA)

- OCS Pelletising System

- OCS Pellet Transport System (PTS)

Sales Team

T +49 2302 95622-0

F +49 2302 95622-33

info@ocsgmbh.com

www.ocsgmbh.com

Address

OCS Optical Control Systems GmbH

Wullener Feld 24

58454 Witten

Germany