TDE

Effective process optimisation in the production of LDPE by means of online quality control using the OCS OP5

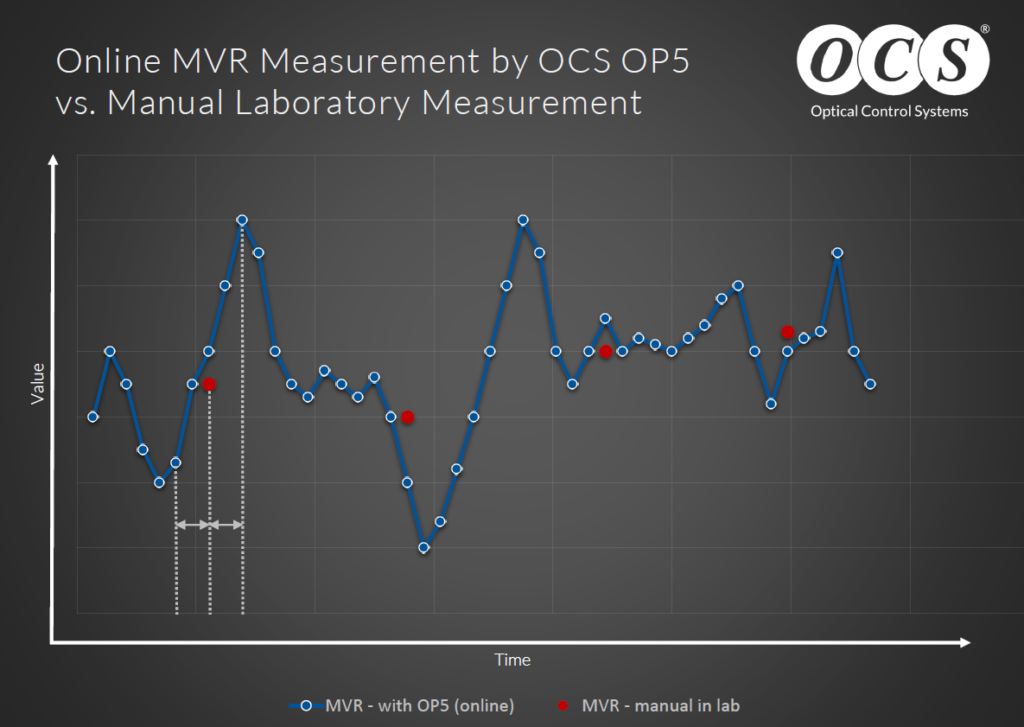

“Quality control has always been important to us. But we were not really aware at the beginning that we could also ensure a considerable process optimisation by means of the OP5. At first, the measuring device delivered results that seemed irreal to us. This was solely due to the fact that even several daily laboratory measurements could not adequately reflect the dynamic changes in production. These variations only became visible through the short measuring interval of the automated OP5 online measurement. The continuous quality control with the use of the OP5 allows us to optimise the production process at any time and at the same time to finally classify our batch material. The advantages such as the fully automated measurement, the considerable time savings through the reduction of transition times and the high reproducibility through the OCS equipment, in comparison to the manual ISO1133 measurement, contribute to an effective process optimisation and reduction.“

David Cerra González, Quality Coordinator at Transformadora de Etileno A.I.E. (TDE), Spain

Plastics are produced in countless variants today. The most common is polyethylene. Modern processes mean that there are also different variations of this material today. Low-density polyethylene, or LDPE, produced using a high-pressure process, is one of them.

Transformadora de Etileno A.I.E. (TDE) has three plants for the production of low density polyethylene (LDPE) in Spain. The annual capacity of LDPE is approximately 160,000 t/year.

TDE focuses on continuous quality control and assurance in the ongoing production process in order to detect and optimise dynamic production fluctuations at an early stage and in a relatively short sequence. For this reason, two OP5 measuring systems are already in use in two of three production lines. Various deviations in production have an impact on viscosity and can therefore be monitored by online viscosity measurement using OP5. The continuous measurement of the Melt Index (MI) of polymer samples also allows a final classification of the batch material.

Save time and reduce costs. Due to the continuous measurement, real-time results can be visualised in 5 to 10 minutes via the touch panel with a data trend in 24/7 operation. This leads to considerable time savings compared to a manual ISO 1133 measurement. The permanent data logging makes it possible to intervene significantly in the production process and save costs.

High reproducibility through OP-MFR measurement. The OP5 MFR measurement is a method carried out by means of exact control of the melt flow in combination with a high-precision and self-developed melt pressure measurement. This method achieves a typical reproducibility of +/- 1 % in comparison to the manual ISO 1133 measurement with +/- 5-10 % deviation.

Are you interested in a detailed performance description in a 1-to-1 conversation with our experts? Then please feel free to contact us.

Learn more about the features of the OP5 here.

Note: If the MFR value changes dynamically in production, small time intervals between the sampling of OP5 and laboratory measureme nt

are sufficient to result high differences. The high fluctuations are now shown by the high measuring rate of the online measu rem ent of the

OP5 . © OCS Optical Control Systems GmbH