Bottle Cap Test (BCT100)

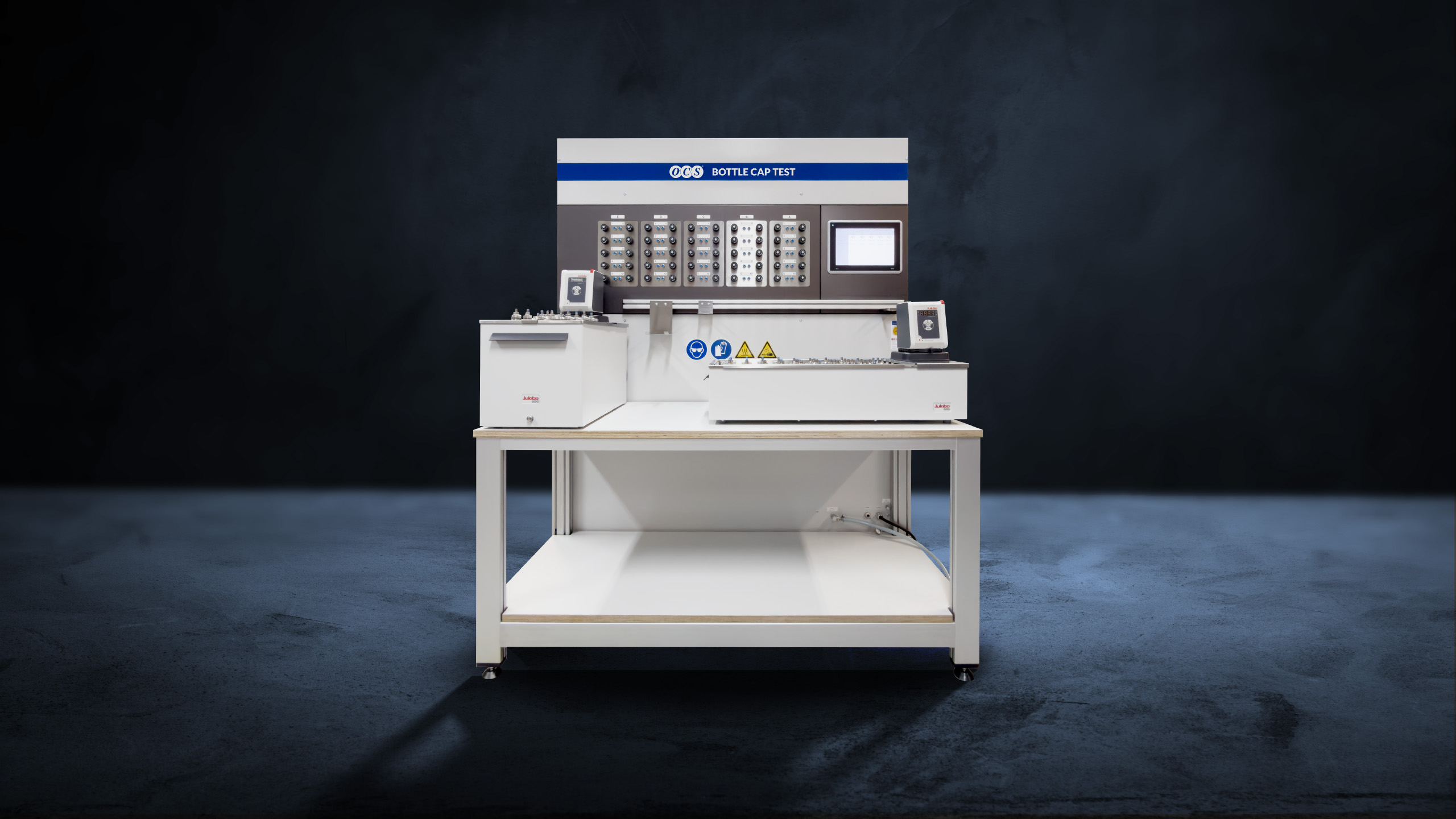

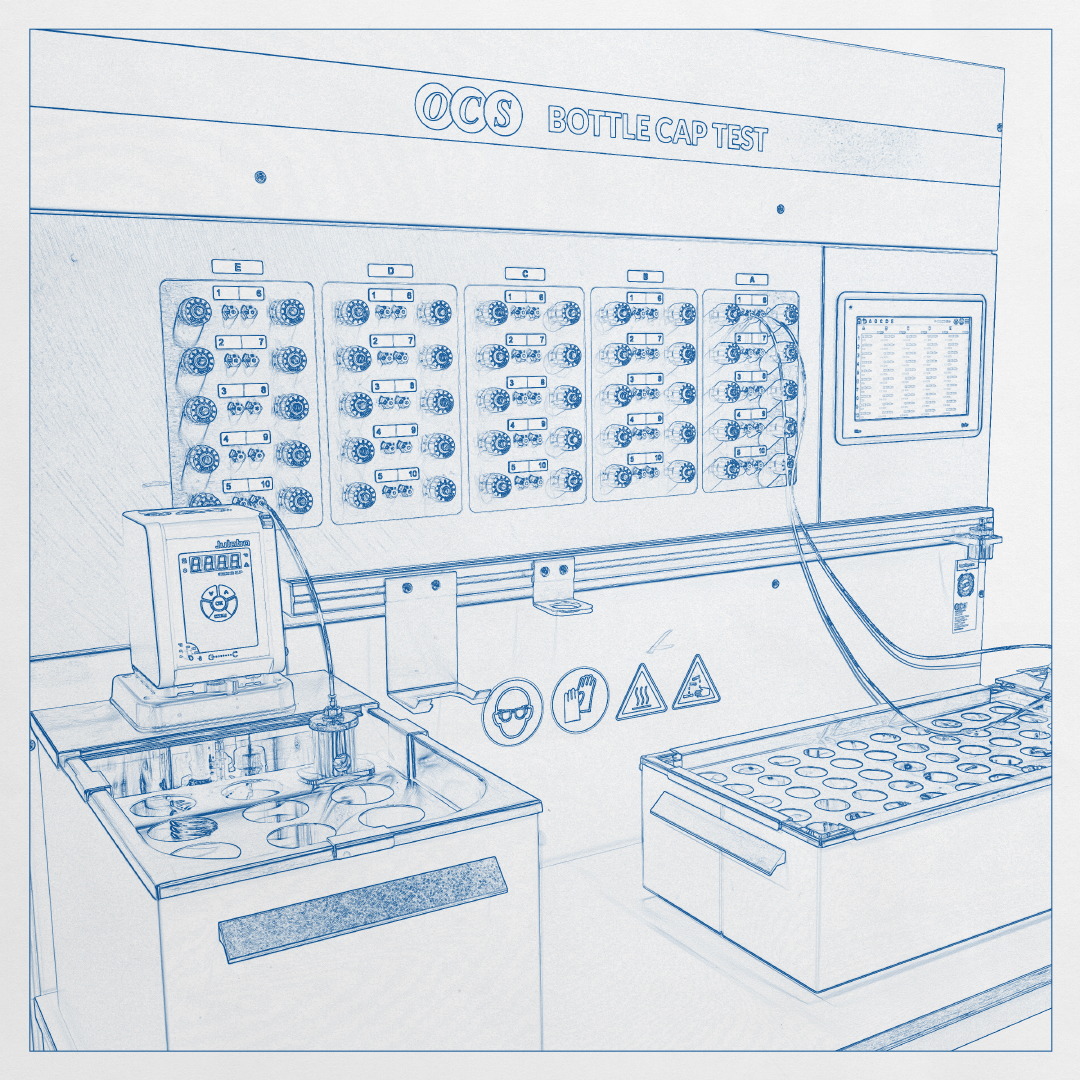

The OCS Bottle Cap Test (BCT100) is a compact solution for testing bottle caps and plastic bottles for crack resistance under combined chemical and mechanical stress in the laboratory. The system has 50 independent measuring stations, distributed across 5 measuring groups, which can be used flexibly for cap or bottle testing. The equipment includes a compressed air system, temperature-controlled wetting agent baths and a touchscreen control panel. The electronics are housed in a lockable, water-resistant control cabinet.

Testable Raw Materials

- Polyethylene materials

Features

- 50 measuring stations in 5 groups, each with individual load settings

- Wide range of load conditions possible (temperature, pressure, leakage and wetting agent)

- Precise and continuous measurement and documentation of test conditions

- Uniform bath temperature control in 2 independently usable baths

- No time limit on test times, time resolution: 1 sec. (real time)

- Operation via modern touch panel technology

- Visual and acoustic alarm functions for maximum safety

- Flexible and scalable trend visualization

- High chemical resistance of the materials used

- Individually configurable report output

- Flexible and secure data connection with state-of-the-art communication standards

Sales Team

T +49 2302 95622-0

F +49 2302 95622-33

info@ocsgmbh.com

www.ocsgmbh.com

Address

OCS Optical Control Systems GmbH

Wullener Feld 24

58454 Witten

Germany